聯系 - 熱線

聯系 - 熱線

聯系 - 熱線

聯系 - 熱線

解析然氣發電機組會出現哪些問題,怎么解決的?

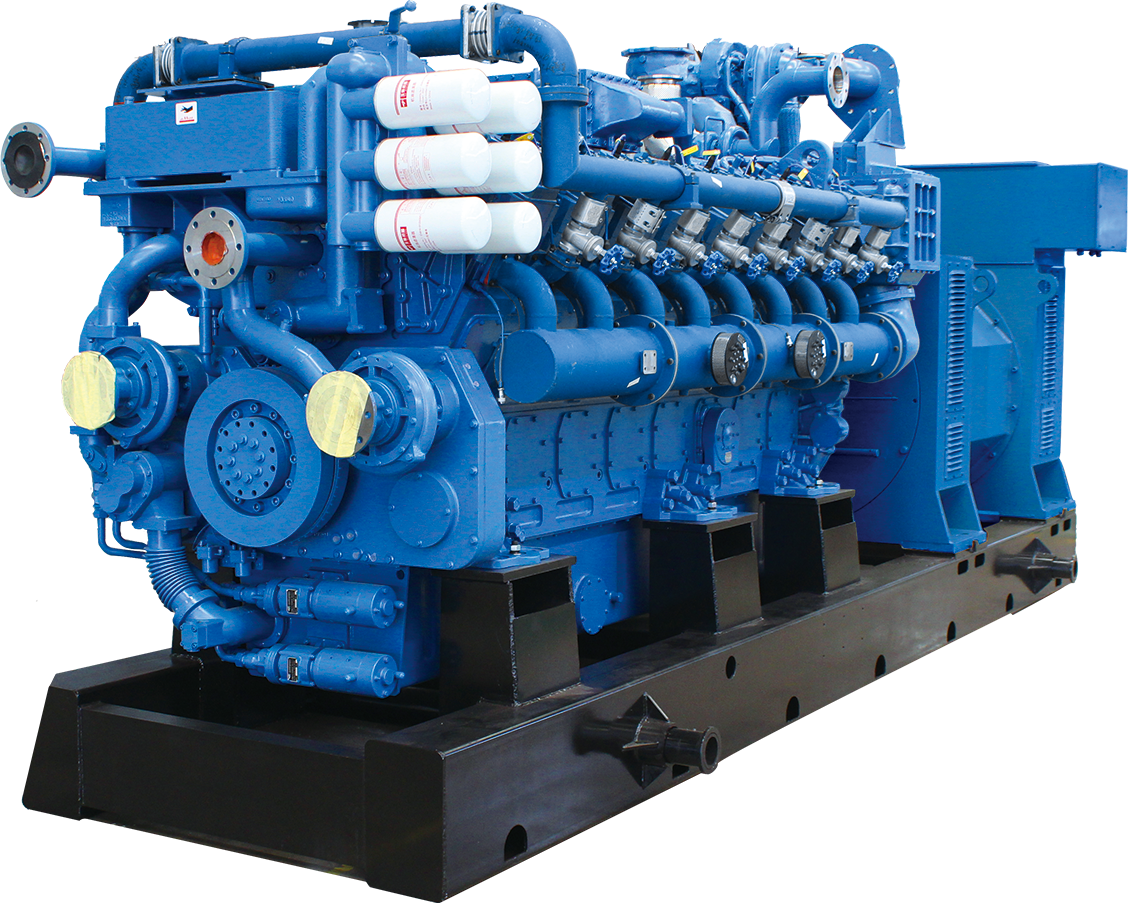

燃氣發電機組作為能源領域實現能量高效轉換的關鍵設備,在長時間不間斷運行過程中,不可避免地會遭遇一系列復雜的技術問題,這些問題涵蓋機械、電氣、控制系統以及燃氣系統等多個重要方面,以下將進行全面且深入的解析。

As a key equipment for achieving efficient energy conversion in the energy field, gas generator sets inevitably encounter a series of complex technical problems during long-term uninterrupted operation. These problems cover multiple important aspects such as mechanical, electrical, control systems, and gas systems. The following will provide a comprehensive and in-depth analysis.

在機械系統故障層面,發動機異常振動是較為突出的問題之一。其產生的根源主要涉及曲軸不平衡,當曲軸因制造缺陷或長期使用出現質量分布不均時,在高速運轉下便會引發振動;軸承磨損也是重要原因,長期的摩擦使得軸承間隙增大,無法有效支撐曲軸運轉,從而產生振動;飛輪松動會破壞整體轉動的穩定性,進而導致振動;基礎固定不牢,地腳螺栓松動或基礎結構設計不合理,無法為發動機提供穩固支撐,同樣會引發振動。針對這些問題,有效的解決方案包括使用激光對中儀對曲軸同心度進行精準校正,將偏差嚴格控制在≤0.05mm 的范圍內,以確保曲軸運轉平穩;選用 SKF、FAG 等高品質品牌軸承,并且建議在運行 8000 小時后進行強制更換,保證軸承的可靠性;采用扭矩扳手按照廠家規定的扭矩值緊固地腳螺栓,增強基礎的穩固性。而缸體過熱(溫度>95℃)同樣是機械系統常見故障,其原因主要有冷卻系統故障,當水泵效率下降超過 15% 時,冷卻液循環不暢,無法及時帶走熱量;缸套結垢,若水垢厚度超過 0.5mm,會嚴重影響熱傳導效率;潤滑油路堵塞,導致潤滑不良,部件摩擦產生大量熱量。對應的解決措施為使用高壓水槍配合專用清洗劑對散熱器進行徹底清洗,恢復其散熱性能;選用濃度在 40%-60% 的乙二醇基冷卻液,保證冷卻效果;安裝在線油壓監測系統,將預警值設定為<2bar,以便及時發現潤滑油路異常。

At the level of mechanical system failures, abnormal engine vibration is one of the more prominent issues. The root cause of its occurrence mainly involves the imbalance of the crankshaft. When the crankshaft has uneven mass distribution due to manufacturing defects or long-term use, it will cause vibration during high-speed operation; Bearing wear is also an important cause. Long term friction increases the clearance between bearings, which cannot effectively support the operation of the crankshaft, resulting in vibration; Loose flywheels can disrupt the overall stability of rotation, leading to vibration; Poor foundation fixation, loose anchor bolts or unreasonable foundation structure design, which cannot provide stable support for the engine, can also cause vibration. Effective solutions to these issues include using a laser alignment instrument to accurately correct the concentricity of the crankshaft, strictly controlling the deviation within a range of ≤ 0.05mm to ensure smooth operation of the crankshaft; Select high-quality brand bearings such as SKF and FAG, and it is recommended to replace them forcibly after 8000 hours of operation to ensure the reliability of the bearings; Use a torque wrench to tighten the anchor bolts according to the manufacturer's specified torque value, enhancing the stability of the foundation. Overheating of the cylinder body (temperature>95 ℃) is also a common fault in mechanical systems, mainly caused by cooling system failures. When the efficiency of the water pump decreases by more than 15%, the circulation of coolant is not smooth, and heat cannot be taken away in a timely manner; If the thickness of the scale on the cylinder liner exceeds 0.5mm, it will seriously affect the thermal conductivity efficiency; The blockage of the lubrication oil circuit leads to poor lubrication and generates a large amount of heat due to component friction. The corresponding solution is to thoroughly clean the radiator with a high-pressure water gun and a specialized cleaning agent to restore its heat dissipation performance; Select ethylene glycol based coolant with a concentration of 40% -60% to ensure cooling effect; Install an online oil pressure monitoring system and set the warning value to<2 bar to promptly detect any abnormalities in the lubrication system.

電氣系統故障方面,輸出電壓波動(±10%)是常見問題。AVR 調節器響應延遲(>50ms),在負載變化時無法及時調整勵磁電流,導致電壓波動;轉子繞組匝間短路,使得繞組阻抗變化超過 15%,影響發電性能;負載突變,當負載變化超過 30% 額定負荷時,超出了發電機的調節能力,也會造成電壓波動。解決這些問題需要升級數字式 AVR,將響應時間縮短至<20ms,提高調節靈敏度;采用 Megger 對轉子絕緣進行測試,若阻值<1MΩ 則需及時檢修,避免短路故障擴大;加裝負載緩沖裝置,減小負載突變對電壓的影響。

In terms of electrical system faults, output voltage fluctuations (± 10%) are a common problem. AVR regulator response delay (>50ms), unable to adjust excitation current in a timely manner when load changes, resulting in voltage fluctuations; Short circuit between turns in the rotor winding causes a change in winding impedance exceeding 15%, affecting power generation performance; Load mutation, when the load changes by more than 30% of the rated load, exceeds the regulating capacity of the generator and can also cause voltage fluctuations. To solve these problems, it is necessary to upgrade the digital AVR, shorten the response time to<20ms, and improve the adjustment sensitivity; Use Megger to test the rotor insulation. If the resistance value is less than 1M Ω, timely maintenance is required to avoid the expansion of short circuit faults; Install load buffering devices to reduce the impact of sudden load changes on voltage.

控制系統故障中,PLC 誤動作較為常見。EMI 干擾,當場強>10V/m 時,會對 PLC 的正常運行產生干擾;程序死循環,導致掃描周期超過 200ms,影響系統響應;通訊中斷,誤碼率>10?? 時,數據傳輸不準確。改進措施包括實施三級屏蔽,對信號線、柜體以及接地進行全面屏蔽,減少電磁干擾;優化 PLC 程序,增加看門狗功能,防止程序死循環;改用光纖通訊,將衰減控制在<0.5dB/km,提高通訊的穩定性和準確性。燃氣閥組故障也是控制系統的常見問題,伺服電機過載,當電流超過額定值 120% 時,會影響燃氣閥的正常調節;位置傳感器漂移,偏差超過 ±1% FS,導致燃氣流量控制不準確。針對這些問題,可通過加裝力矩限制器,保護伺服電機;采用非接觸式磁編碼器,其分辨率達 0.1°,提高位置檢測的精度。

PLC misoperation is more common in control system failures. EMI interference, when the field strength is greater than 10V/m, will interfere with the normal operation of PLC; Program dead loop, resulting in a scanning cycle exceeding 200ms, affecting system response; Communication interruption, error rate>10?? At that time, the data transmission was inaccurate. Improvement measures include implementing three-level shielding, comprehensively shielding signal lines, cabinets, and grounding to reduce electromagnetic interference; Optimize PLC program, add watchdog function to prevent program dead loop; Switch to fiber optic communication and control attenuation to<0.5dB/km to improve communication stability and accuracy. Gas valve group failure is also a common problem in control systems. When the servo motor is overloaded and the current exceeds 120% of the rated value, it will affect the normal adjustment of the gas valve; The position sensor drifts with a deviation exceeding ± 1% FS, resulting in inaccurate gas flow control. To address these issues, torque limiters can be installed to protect servo motors; Adopting a non-contact magnetic encoder with a resolution of 0.1 °, it improves the accuracy of position detection.

本文由解析氣發電機組友情奉獻.更多有關的知識請點擊:http://www.asianelephant.cn我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is a friendly contribution from the analysis of gas generator sets For more information, please click: http://www.asianelephant.cn We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

業務分類

Business classification產品推薦

product recommendation聯系方式

Contact Information

截屏,微信識別二維碼