Ø In cylinder mixing technology (safety):

Gas and air are mixed in the cylinder, and a set of gas timing injection devices is installed in each cylinder corresponding to the intake pipes on both sides. After the main exhaust valve is closed and the main inlet valve is opened, this device relies on the timing cam of the transmission to open the gas valve at a fixed time to inject gas into the cylinder, allowing the gas and air to mix in the cylinder (the gas intake volume of a single cylinder can be adjusted based on the exhaust temperature detection of each cylinder), solving the problem of backfire blasting in the intake pipe. In order to adapt to the fast combustion characteristics of hydrogen in gas, a dual valve device is adopted to shorten the intake time. At the same time, the dual valve injection can fully mix the refining gas and air, resulting in more complete combustion.

Ø Constant pressure exhaust system

Adopting a constant pressure exhaust system to solve the problem of uneven operation of each cylinder in the pulse exhaust system.

Ø Dual control air fuel ratio mixing technology:

Adopting dual control air fuel ratio mixing technology with separate air and gas control, achieving real-time control of the engine's fuel ratio during operation. This technology is suitable for the air fuel ratio of most gases.

Gas requirements:

Before entering the machine, the gas should be treated with dust removal, tar, benzene, naphthalene, desulfurization, dehydration and cooling to meet the following requirements: The gas temperature in the main pipeline is ≤40℃, the pressure is 150-200kPa, the pressure change rate is ≤1kPa/min, the tar content is ≤50mg/Nm3, the H2S content is ≤50mg/Nm3, the total sulfide content is ≤200mg/Nm3, the NH3 is ≤20mg/Nm3, the impurity particle size is ≤5μm, and the tar content is ≤50mg/ nm3. Impurity content ≤30mg/Nm3, moisture content ≤40g/Nm3, no free water, H2 volume content < 60%.

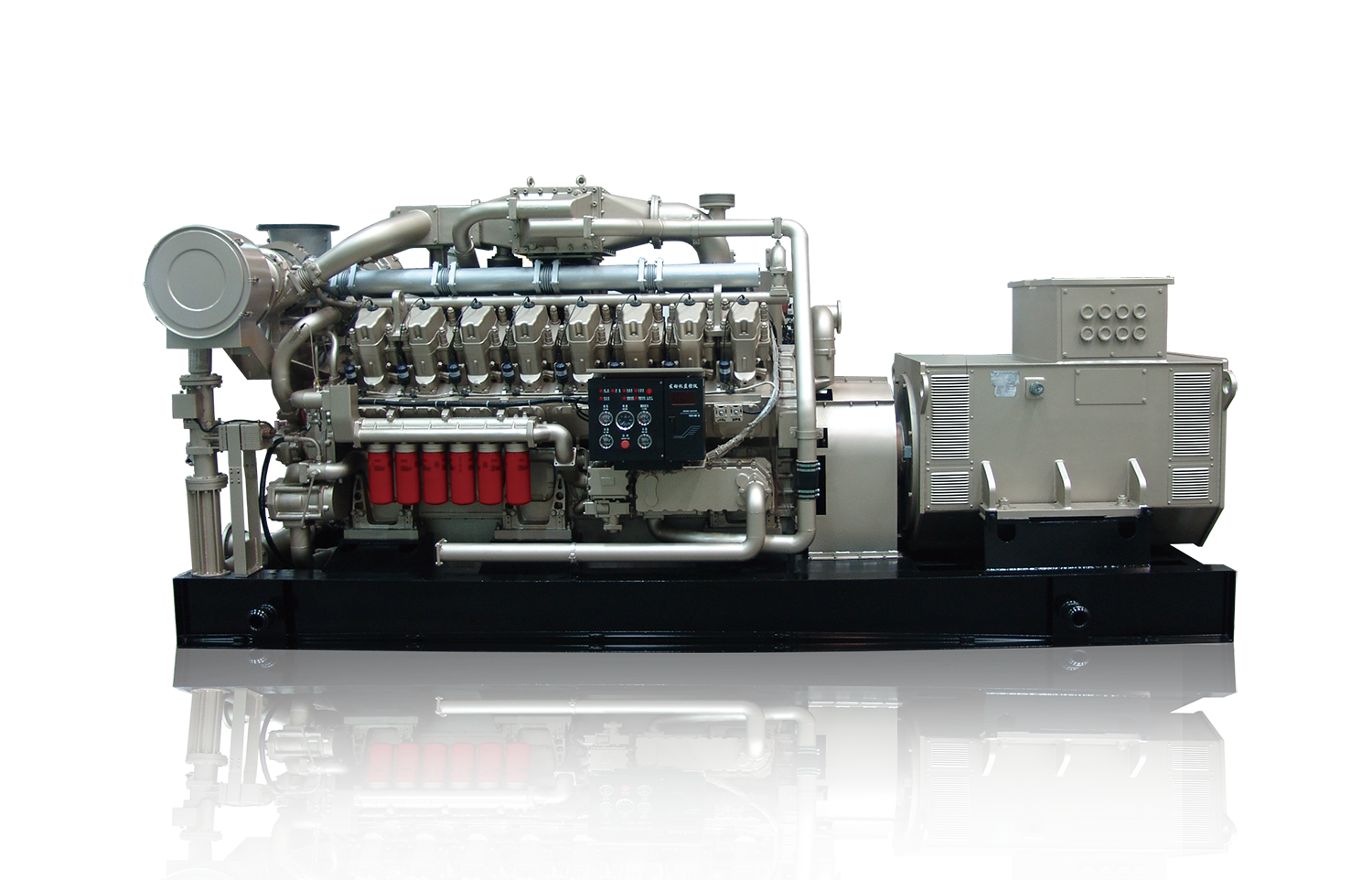

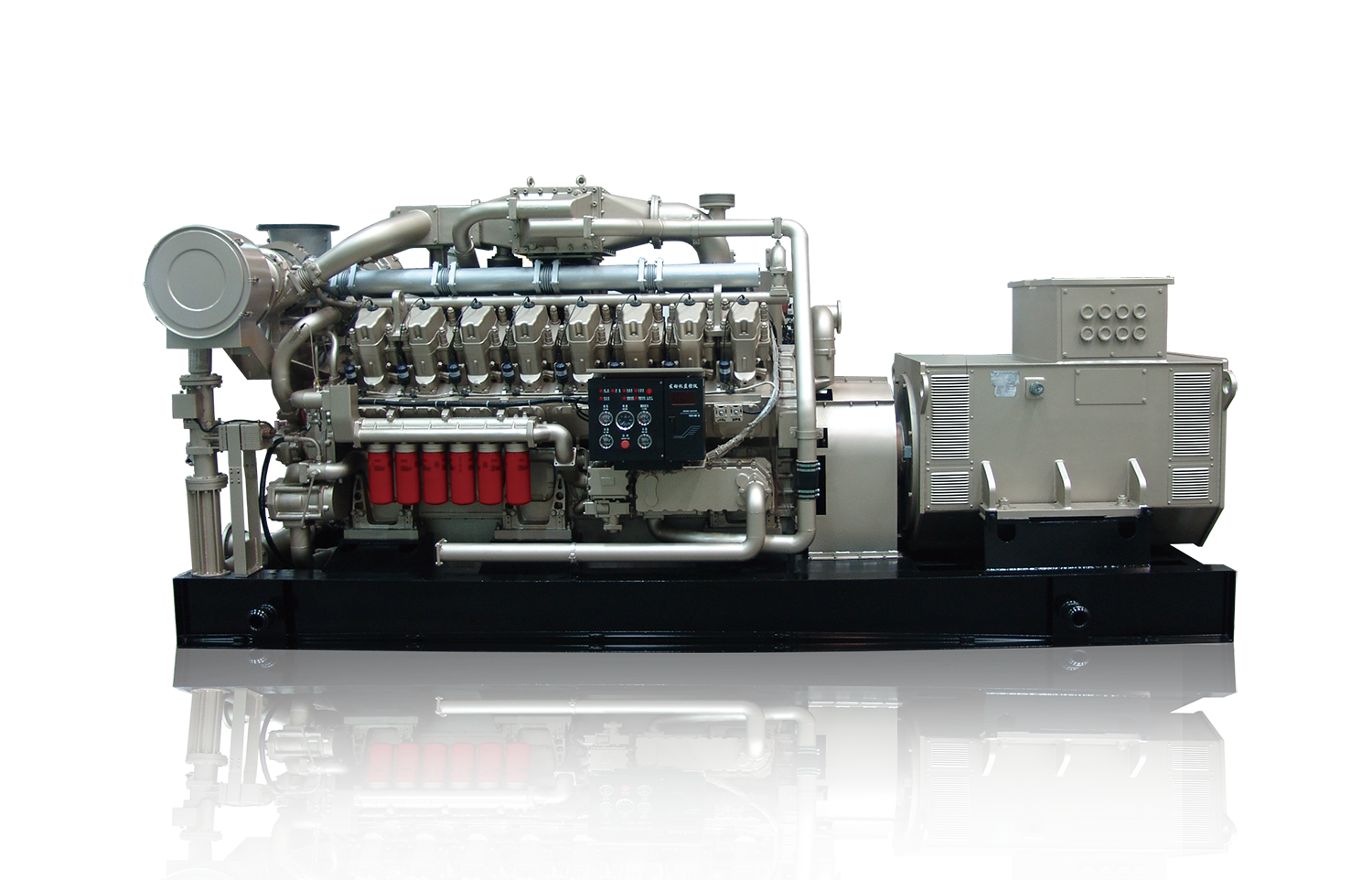

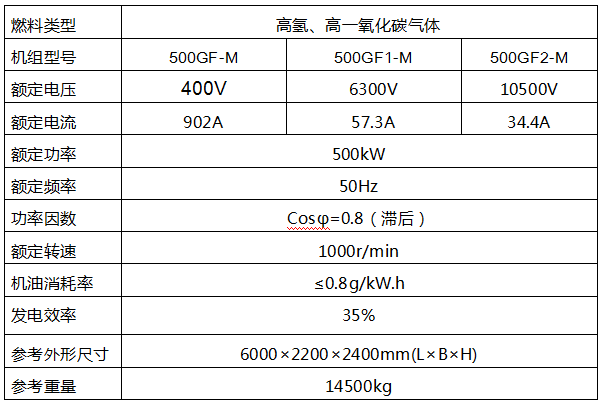

Technical characteristics

Technical characteristics

Tel:0531-69953988

Tel:0531-69953988  Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone

Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone