What should be paid attention to when grinding the crankshaft of natural gas generator sets?

The smooth grinding of the crankshaft of natural gas generator set is one of the key processes to ensure the repair quality. When the outer circle surface of the timing gear journal and the flywheel flange is used as the basis for smooth grinding, the curvature must be corrected before grinding, and the runout of the intermediate main journal before grinding shall not be greater than 0.3 mm. If the bending is not corrected in advance, after weaving, the crankshaft will produce a new axis that intersects with the original flywheel flange and the axis of the timing gear, which changes the turning radius, destroys the dynamic balance force, shortens the service life, and intensifies the wear of relevant parts. The noise of the timing gear is also loud, and the rear oil seal leaks, which increases the unbalanced rotating quality of the engine.

It is one of the key issues of repair quality to strictly ensure that the size of the fillet radius of the crankshaft journal of the natural gas generator set meets the drawing requirements. However, the general car repair shop does not pay enough attention to this. The grinding wheel is rarely polished, and the radius of the polished fillet is often smaller than the specified size. According to statistics, the fillet radius is less than 2.5 mm, and its fatigue strength is only less than 80% of that of 2.5 mm. Since the grinding wheel for smooth grinding of crankshaft is often trimmed with the grinding wheel fillet corrector attached to the grinding machine, so that the size of the grinding fillet meets the requirements, there has been no broken shaft since the vibration surfacing was put into production.

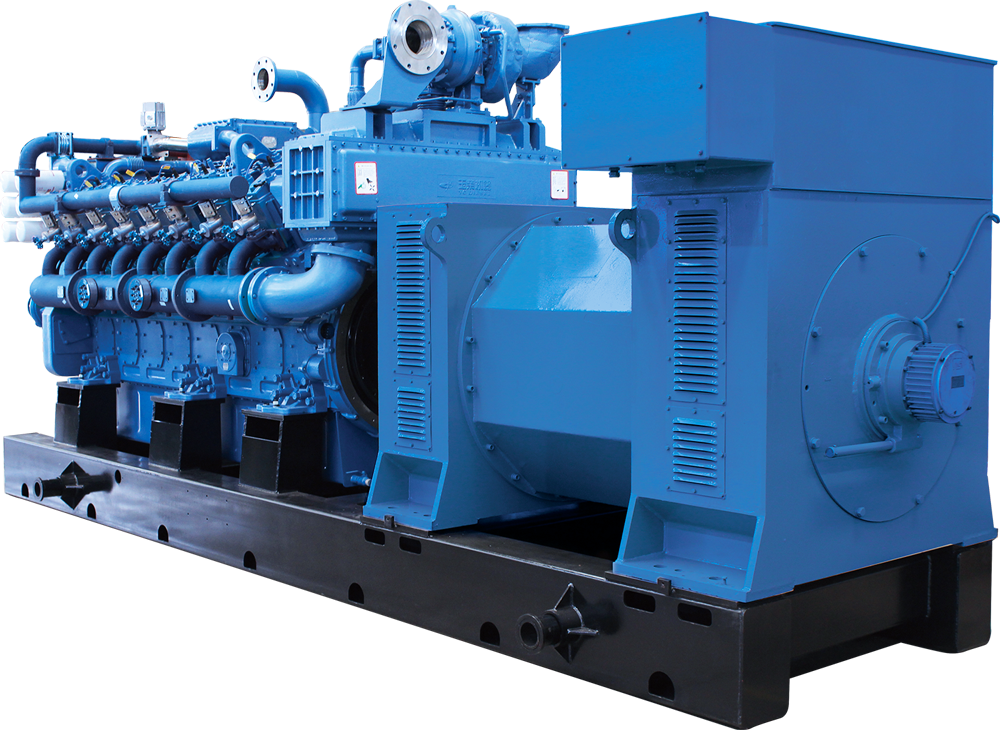

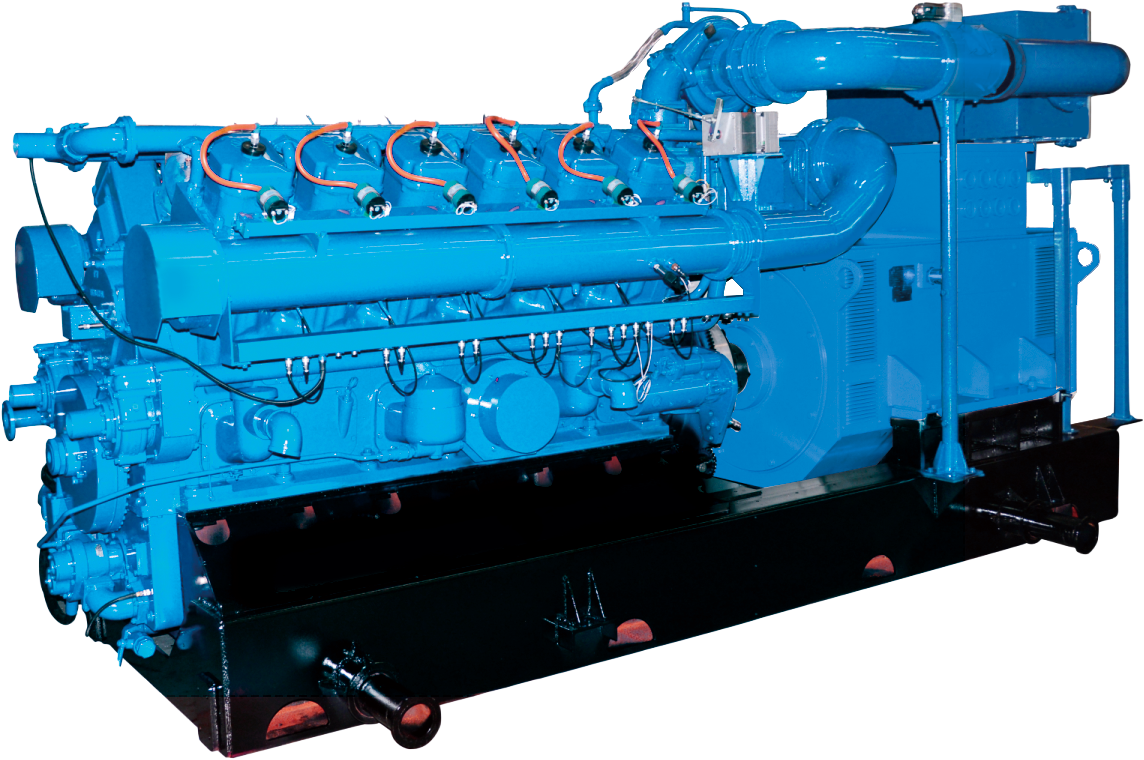

During the operation of natural gas generator set, due to the complex stress and working conditions of the crankshaft, the sliding speed of each friction surface is very high, and the heat dissipation condition is poor. Therefore, the main journal and connecting rod journal of the crankshaft will inevitably wear during the operation, and the wear is uneven. The main performance is that the journal has roundness, cylindricity exceeds the standard value and strain. The most worn part of the connecting rod journal is generally on the inner side of each journal, that is, on the side of the crankshaft centerline, so that the journal is out of round; The parts that wear into a cone are generally on the side where the impurities in the lubricating oil channel attach and the parts with large stress. Crankshaft main journal_ The wear parts of the engine vary according to the degree of strengthening of the engine, the number of cylinders, the length of the crankshaft and the counterweight of the balance weight, and the wear is more uniform than that of the connecting rod journal. Practice shows that the wear of connecting rod journal is faster than that of main journal, but the wear of main journal is more serious than that of connecting rod journal.

Inspection and treatment methods of natural gas generator set. Find out the worn part according to the wear rule of each journal, and measure its roundness and cylindricity with an outside micrometer to determine the repair level and grinding size of the crankshaft.

The smooth grinding of crankshaft is one of the key processes to ensure the repair quality. When the outer circle surface of the timing gear journal and the flywheel flange is used as the basis for smooth grinding, the curvature must be corrected before grinding, and the runout of the intermediate main journal before grinding shall not be greater than 0.3 mm. If the bending is not corrected in advance, after weaving, the crankshaft will produce a new axis that intersects with the original flywheel flange and the axis of the timing gear, which changes the turning radius, destroys the dynamic balance force, shortens the service life, and intensifies the wear of relevant parts. The noise of the timing gear is also loud, and the rear oil seal leaks, which increases the unbalanced rotating quality of the engine.

It is one of the key issues of repair quality to strictly ensure that the size of the crankshaft journal fillet radius meets the drawing requirements. However, the general car repair shop does not pay enough attention to this. The grinding wheel is rarely polished, and the radius of the polished fillet is often smaller than the specified size. According to statistics, the fillet radius is less than 2.5 mm, and its fatigue strength is only less than 80% of that of 2.5 mm. Since the grinding wheel for smooth grinding of crankshaft is often trimmed with the grinding wheel fillet corrector attached to the grinding machine, so that the size of the grinding fillet meets the requirements, there has been no broken shaft since the vibration surfacing was put into production.

Tel:0531-69953988

Tel:0531-69953988  Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone

Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone